Thepa ea Welding ea Laser bakeng sa Impeller ea Pompo ea Metsi

Tlhaloso

Bakeng sa welding ea laser ea lehare la pompo ea metsi

● Liroboto tsa indasteri tse nang le li-axis tse tšeletseng tse nepahetseng

● Laser + laser welding head system

● laser tjheseletsa hlooho

● Tafole ea rotary ea Duplex/Triplex

● Mojule oa phetisetso ea liroboto

● Multi-station turntable module

● Mokhoa oa ho laola motlakase

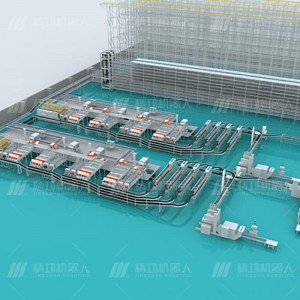

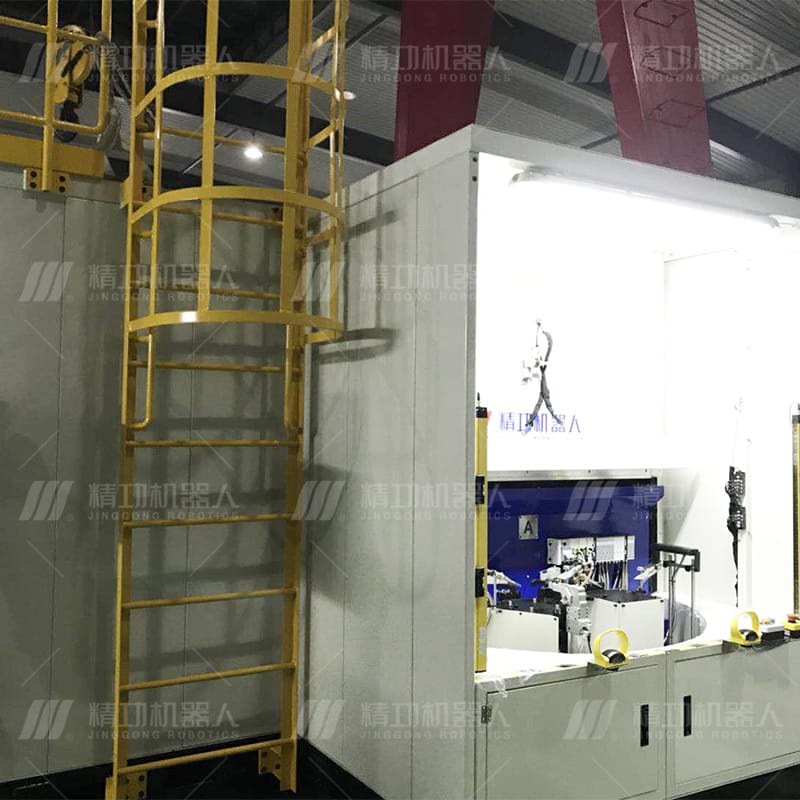

Lintlha tsa Tech

E na le sistimi ea liroboto, sistimi e kopaneng ea laser + welding ea laser, mochini o otlolohileng oa laser welding, sistimi ea kalafo ea mosi le lerōle, sistimi e fetolang maemo a habeli, sistimi e kopaneng ea ts'ireletso ea kamore ea welding le sete ea sistimi ea taolo ea motlakase.Ntle le ho kenya le ho laolla ka letsoho, liketso tse ling kaofela li phethoa ka bo eona.

Melemo

Fetola mokhoa o tloaelehileng oa tlhahiso ea argon arc welding, lebelo la welding, ho nepahala ho phahameng, deformation e nyane ea post-welding, ponahalo e ntle, weld ha e hloke ts'ebetso e latelang (e kang ho phethoha, ho sila, joalo-joalo)

Video ea Sehlahisoa

LBH

P: haeba karolo ea thepa e senyehile, na u ka fana ka likarolo tse tšoanang tsa lisebelisoa?

A: pele thepa e amoheloa, k'hamphani ea rona e ka fana ka likarolo tse tšoanang tsa mahala mahala;Haeba ka nako ea tiisetso, re ka thusa bareki ho reka, haeba ho hlokahala, re ka u rekela

Tlhahlobo ea Mosebelisi

Tlhahisong ea li-batch, boleng ba welding bo tsitsitse

Pontšo ea Sehlahisoa

E na le sistimi ea liroboto, sistimi e kopaneng ea laser + welding ea laser, mochini o otlolohileng oa laser welding, sistimi ea kalafo ea mosi le lerōle, sistimi e fetolang maemo a habeli, sistimi e kopaneng ea ts'ireletso ea kamore ea welding le sete ea sistimi ea taolo ea motlakase.Ntle le ho kenya le ho laolla ka letsoho, liketso tse ling kaofela li phethoa ka bo eona.

Fetola mokhoa o tloaelehileng oa tlhahiso ea argon arc welding, lebelo la welding, ho nepahala ho phahameng, deformation e nyane ea post-welding, ponahalo e ntle, weld ha e hloke ts'ebetso e latelang (e kang ho phethoha, ho sila, joalo-joalo)

P: haeba karolo ea thepa e senyehile, na u ka fana ka likarolo tse tšoanang tsa lisebelisoa?

A: pele thepa e amoheloa, k'hamphani ea rona e ka fana ka likarolo tse tšoanang tsa mahala mahala;Haeba ka nako ea tiisetso, re ka thusa bareki ho reka, haeba ho hlokahala, re ka u rekela

Tlhahisong ea li-batch, boleng ba welding bo tsitsitse

Thepa ea Welding ea Laser bakeng sa Impeller ea Pompo ea Metsi